Agricultural machinery is a good helper for agricultural production and fortune

Not only must be able to purchase, good maintenance, the correct operation, use, maintenance, maintenance of machinery is also very important.

According to Article 23 of the "Regulations on Liability for Repair, Replacement and Return of Agricultural Machinery Products", three guarantees cannot be implemented for any mechanical failure caused by personal reasons. To this end, the majority of operators should pay attention to the following four points:

Carefully read the instruction manual of the machine, master the structure and performance, and avoid swallowing the dates wholeheartedly and being self-righteous.

Second, the operation of the machine should follow the operating procedures, and the maintenance should pay attention to the method.

The functions of agricultural machinery are limited, and there are regulations on the speed of heavy-duty vehicles. Avoid "small horse-drawn carts".

Resolutely do not operate the diseased machinery. Once the machinery is found to be faulty, the operation should be stopped immediately and maintenance should be carried out in time.

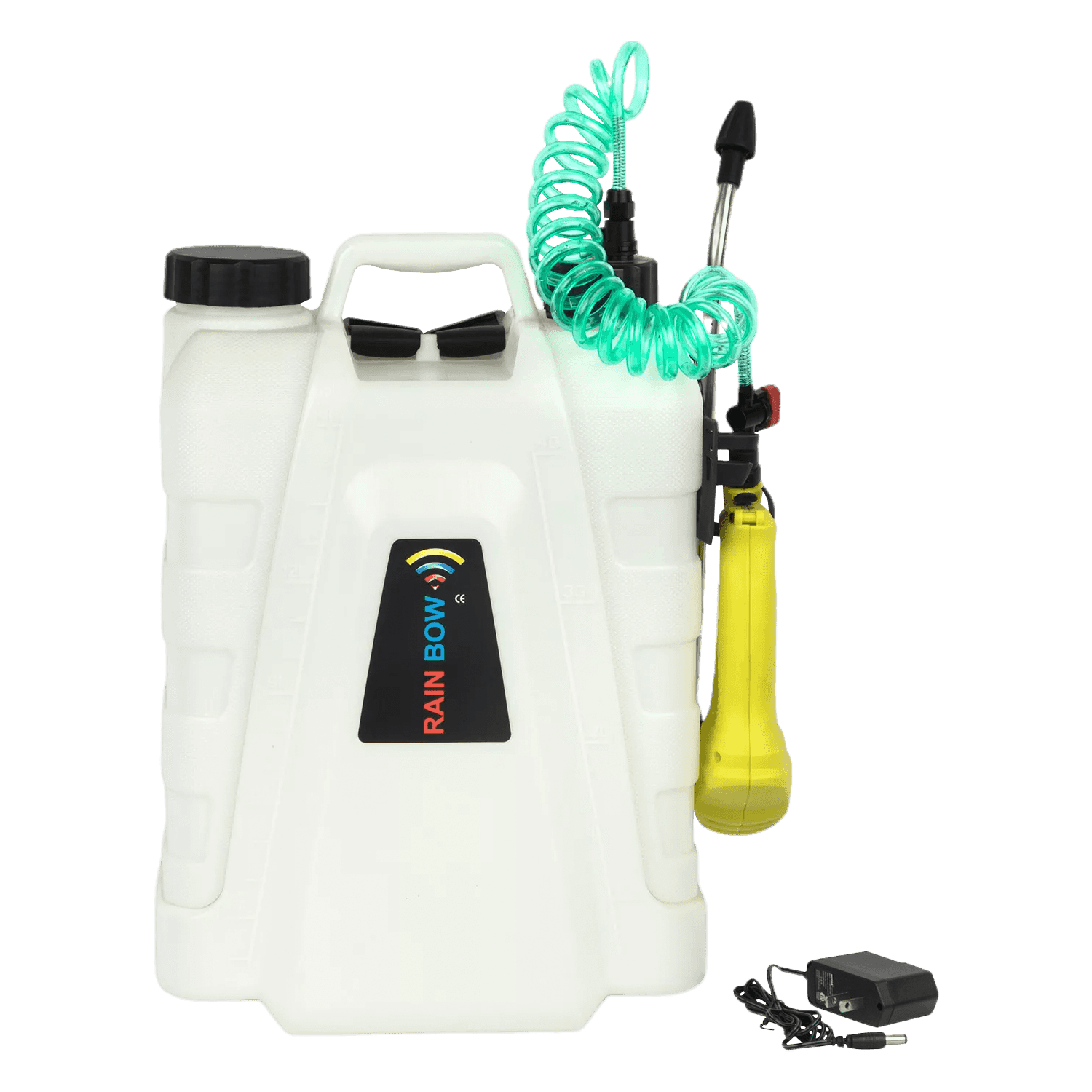

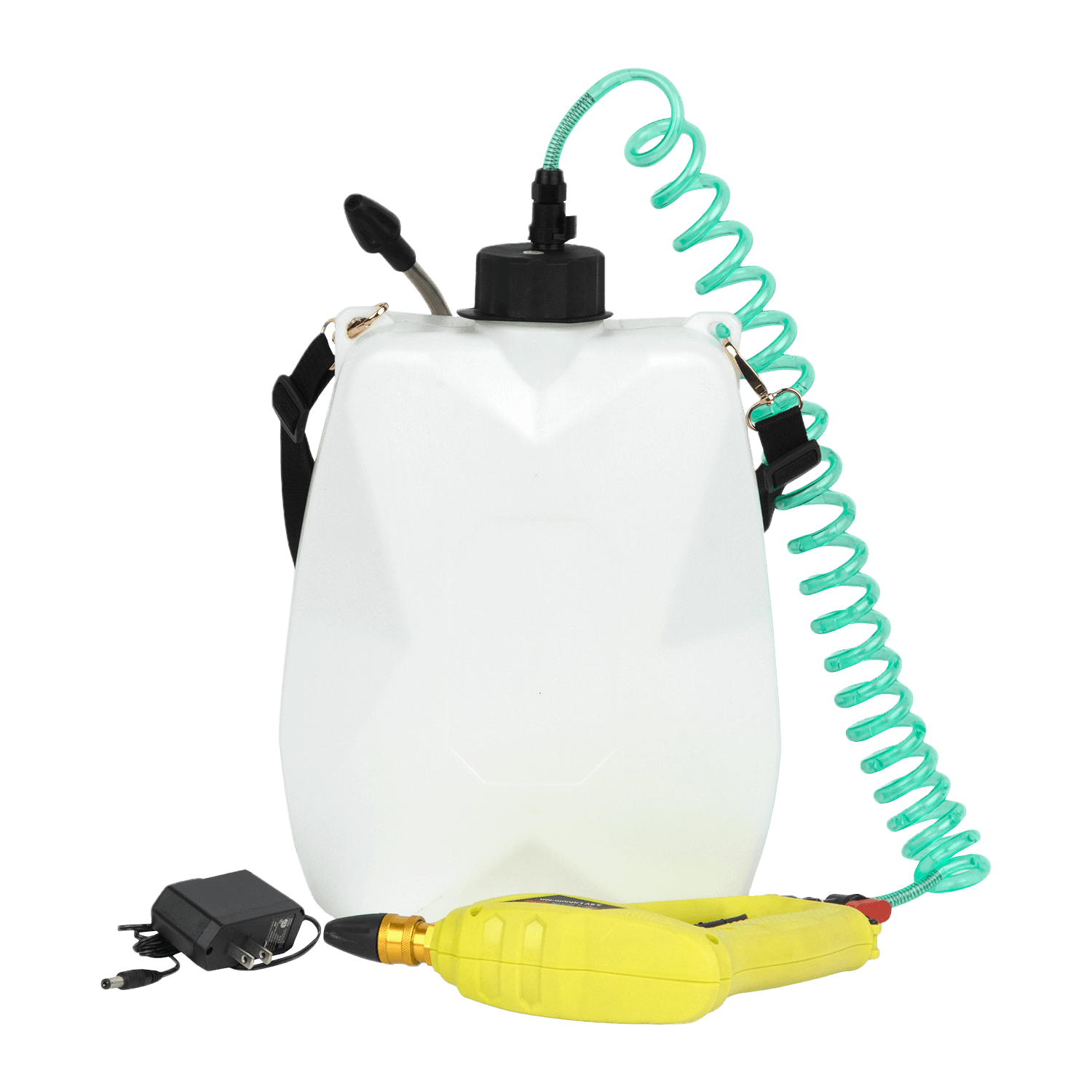

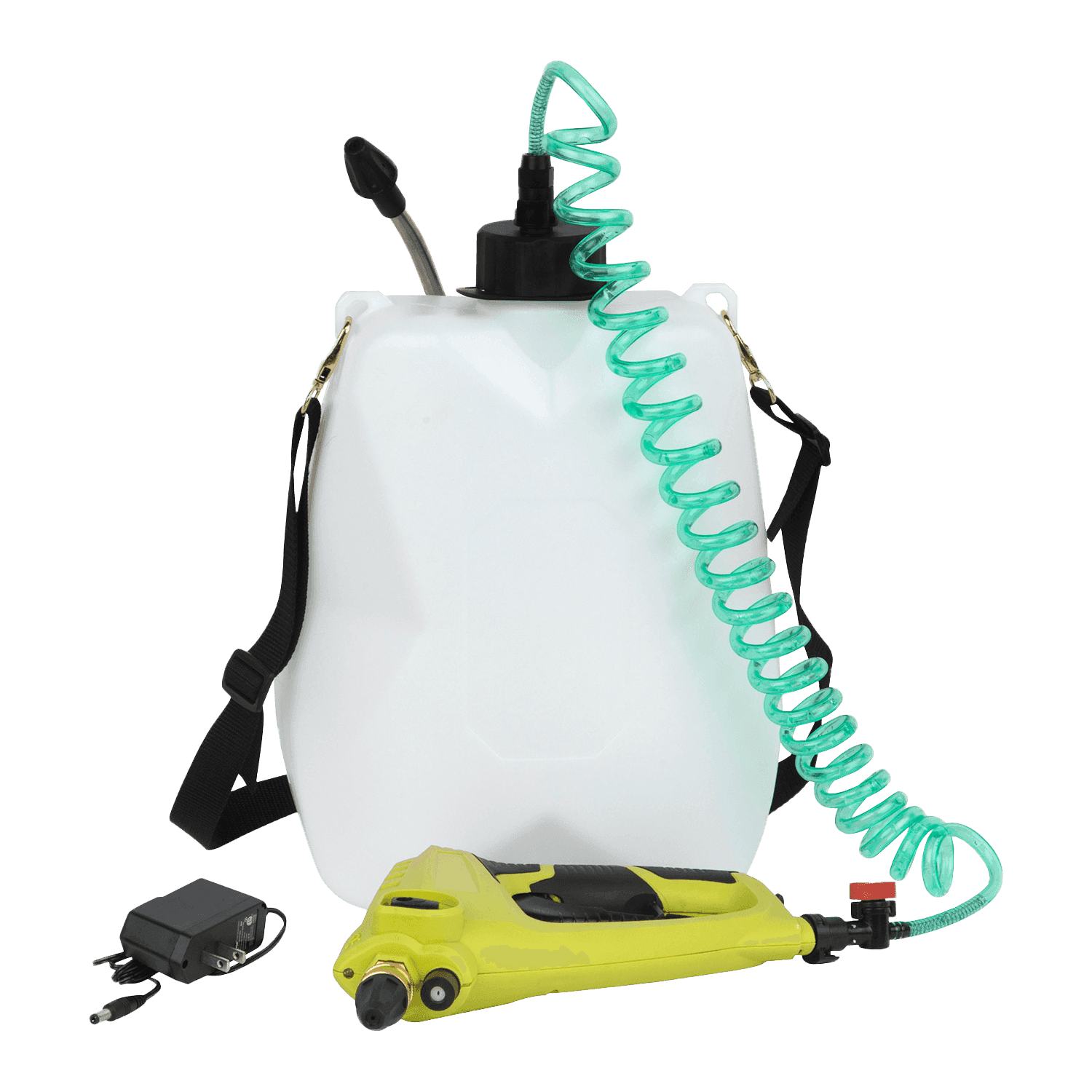

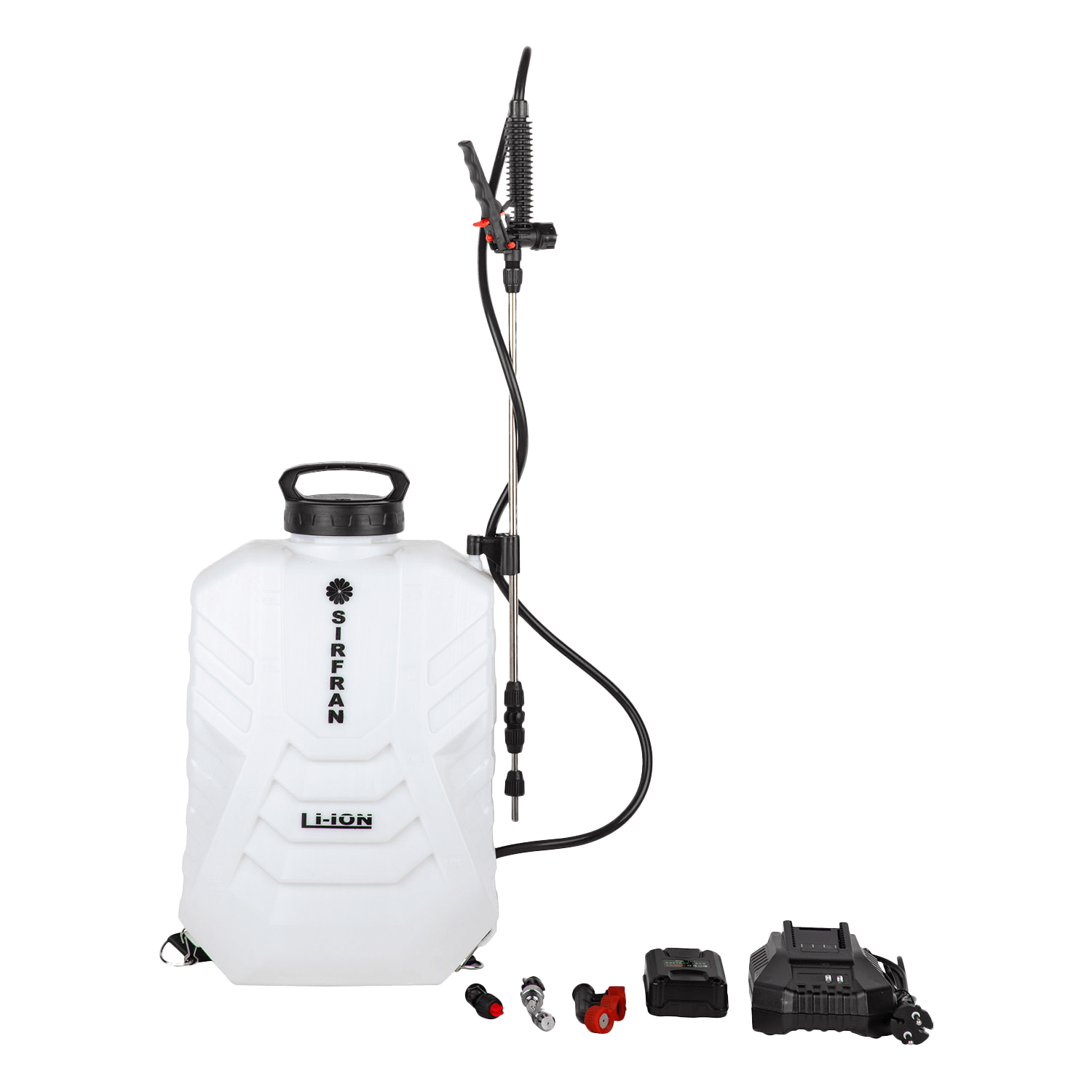

How to use a technical knapsack sprayer

knapsack sprayer

1. To install the sprayer parts correctly. Check each connection for air leakage. When using it, install clean water to test spray first, and then install chemicals.

2. When using it formally, add the medicine first and then add the water. The liquid level of the medicine should not exceed the safe water level. Before spraying, turn the rocker more than 10 times to make the air pressure in the barrel rise to the working pressure. Do not use too much force when pulling the rocker to prevent the air chamber from exploding.

3. When the chemical solution is first loaded, since the air chamber and the spray rod contain clean water, the concentration of the liquid chemical sprayed out in the first 2 to 3 minutes of spraying is low, so attention should be paid to supplementary spraying to avoid affecting the control effect of pests and diseases.

4. After the work is completed, the residual liquid medicine in the barrel should be poured out in time, and washed with clean water and dried. At the same time, check whether there is water in the gas chamber. If there is water, remove the water joint to release the water.

5. If the sprayer will not be used in a short period of time, the main parts should be cleaned, dried and installed, and stored in a cool and dry place. If it is not used for a long time, all metal parts should be coated with butter to prevent rust.

Common faults and troubleshooting methods in use

Insufficient spray pressure and poor atomization: if the water inlet ball valve is put up by dirt, the water inlet valve can be removed and the dirt can be removed with a cloth; if the leather bowl is damaged, a new leather bowl can be replaced; if the connection part is not installed If the sealing ring is damaged or leaks due to damage to the sealing ring, the sealing ring can be added or replaced.

Spray can not be fogged: if the inclined hole of the nozzle body is blocked by dirt, the inclined hole can be cleared; if the nozzle hole is blocked, the nozzle hole can be disassembled and cleaned, but hard objects such as iron wire or copper needle cannot be used to poke the nozzle hole to prevent the hole from expanding. , make the spray quality worse; if the filter in the casing is blocked or the water valve ball is put up, the filter screen and the dirt on the ball should be cleaned.

The switch leaks or cannot be screwed: if the switch cap is not tightened, the switch cap should be tightened; if the washer on the switch core is worn, the washer should be replaced; the switch cannot be screwed, the reason is that the switch has been placed for a long time or has been used for a long time. The core is adhered due to the corrosion of the chemical, so the parts should be removed and cleaned in kerosene or diesel; if it is difficult to remove, it can be soaked in kerosene for a period of time, and then disassembled to remove it. Do not beat it with hard objects.

Water leakage at each connection: if the joint is loose, tighten the nut; if the washer is not leveled or damaged, the washer should be leveled, or the washer should be replaced; if the washer shrinks and hardens, it can be immersed in animal oil before use .

search to find

英语

英语 中文简体

中文简体 法语

法语 西班牙语

西班牙语

HARDWARE AND PLASTIC PARK,PENGJIE TOWN,LUQIAO AREA,TAIZHOU CITY,ZHEJIANG

HARDWARE AND PLASTIC PARK,PENGJIE TOWN,LUQIAO AREA,TAIZHOU CITY,ZHEJIANG + 86-0576-82725288

+ 86-0576-82725288 info@dongtaico.com

info@dongtaico.com